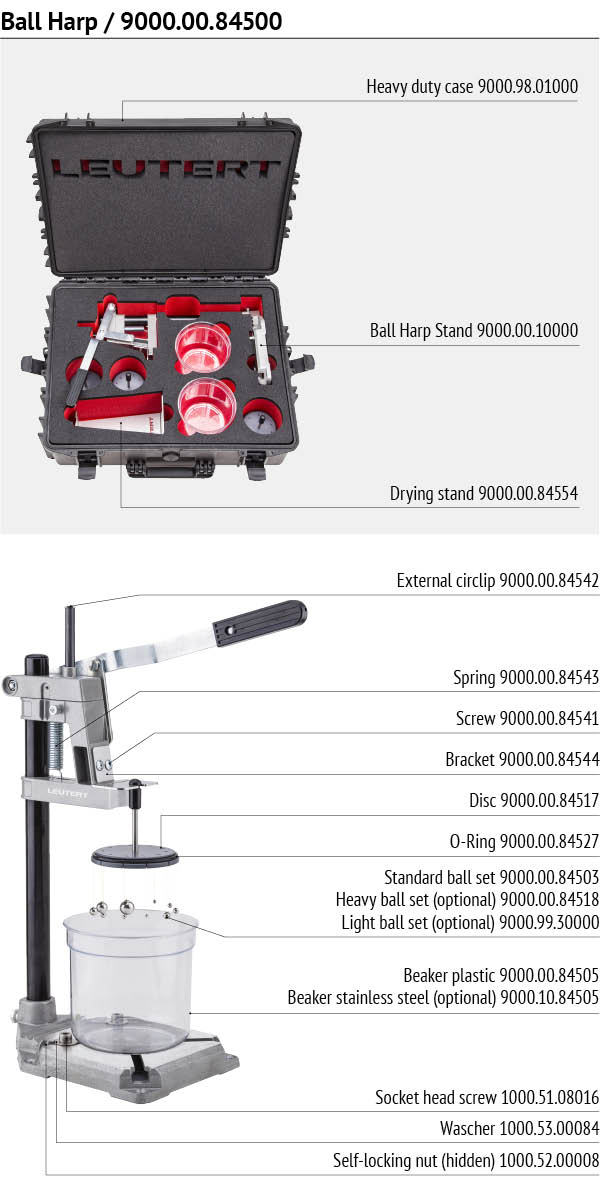

Ball Harp

The Ball Harp test is the recommended test method for supporting fluids used in construction of diaphragm walls according to EN 1538. The Ball Harp consists of several glass and steel balls, each with different diameters. These balls are immersed in the supporting fluid at the same time. With a given density of the supporting fluid, each of these balls is assigned a different yield point. Balls whose yield points are smaller than the yield point of the suspension float. Balls with a yield point greater than the supporting fluid are immersed in it.

The balls of the Ball Harp are numbered 1 to 10 in the order of their increasing yield point. The yield point of the supporting fluid is thus between the yield point of the largest numbered ball that is still floating and the yield point of the smallest numbered ball that is immersed in the fluid.

The yield points of the standard ball set are specified for densities between 1.02 and 1.32 g/cm³ (851.23 and 909.65 lb/gal). Heavy ball sets are available to determine the yield point of higher density suspensions.

The Ball Harp is not only used in diaphragm wall construction. The Ball Harp also helps to adjust the composition of drilling fluids that block invasion and prevent formation damage during drilling operations.